Closing The Loop For

PLASTIC PACKAGING

Introducing SARA rPET by Mohinani Group:

A Sustainable Solution for the PET Waste Management in

Ghana and Nigeria

An Urgent

Challenge

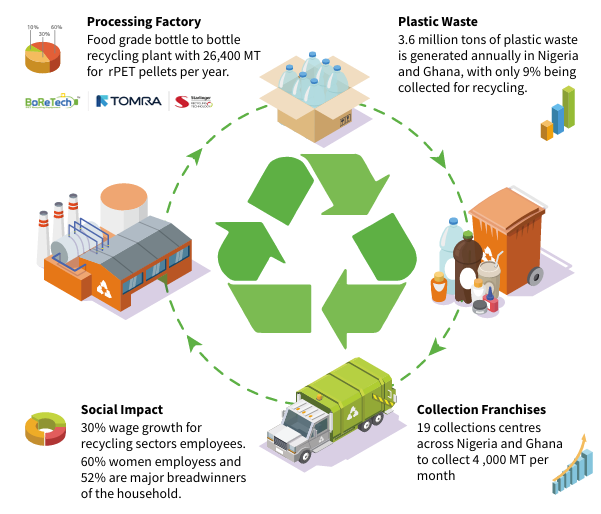

Uncollected waste poses a significant challenge, especially in developing countries where people

struggle with the impacts firsthand. Nigeria ranks as the ninth largest contributor to global plastic

pollution, with an annual production of approximately 2.5 million tons of plastic waste.

Unfortunately, only a mere 12% of this waste is recycled within the country.

Ghana fares no better, where the Ghana National Plastic Action Partnership (NPAP) reports that

around 1.1 million tons of plastic waste are generated annually, with only 5% being collected for

recycling. Predictably, a considerable portion of this waste ends up in various water sources such

as rivers, lakes, drains, lagoons, and ultimately, the ocean.

A Sustainable Solution

The RPET project is actively working to address this pressing issue by boosting the recycling

market and providing sustainable solutions. By establishing franchise collection centers, we have

significantly increased the capacity for plastic waste collection and recycling. In Ghana, our

franchise collection network can handle approximately over 2,000 MT of plastic waste per month, leading to an annual production of 13,200MT of recycled materials.

In Nigeria, with our collection network, we can handle around 2,000 tons of plastic waste per

month, resulting in an annual production capacity of 13,200 MT.

What We Provide

Taking Responsibility For A Sustainable Future

Taking responsibility and raising awareness in society is a crucial aspect of the RPET project for Mohinani Group. We understand that creating a sustainable and efficient recycling ecosystem requires a collaborative effort.

Promoting Awareness

Raising awareness in society about the importance of proper waste management and encouraging the separation of recyclables at the source.

Collection franchises and company-owned facilities

Establishing collection franchises and company-owned facilities to expand the capacity for handling larger volumes of recyclable materials.

Supporting Waste Pickers

Recognizing the vital role of waste pickers and establishing fair partnerships by providing them with tools, resources, and training for effective sorting of recyclables.

Collaboration with government authorities

We collaborate with government authorities to shape sustainable waste management policies

Why Choose Us

Driving Change Through Empowerment

Additional Jobs Creation

By providing essential support, including baling machines, we have significantly strengthened our partner franchises and this in turn, has fueled impressive growth among them. For an instance one particular franchisee has experienced a remarkable increase in monthly collection from 2 to 15 tons and created 10 additional direct jobs and approximately 40 indirect jobs, contributing to local economies and improving livelihoods.

Women Empowerment

Gender equality is a core principle of our project, with 60% of our employees being women and 40% being men. By promoting diversity and inclusivity within the recycling sector, we empower individuals from all backgrounds to actively participate in and contribute to the project's success

WAGE IMPROVEMENT

Our commitment to fairness and environmental standards is upheld through regular audits, ensuring transparency, accountability, and sustainability in all our operations. These audits verify compliance with fair employment policies, guaranteeing that our dedicated workforce benefits from fair wages and safe working conditions. Furthermore, we are proud to have achieved a 30% wage increase for our employees, providing them with improved economic stability and opportunities for growth.

TECHNOLOGICAL ADVANCEMENTS FOR SUPERIOR QUALITY

We recognize the paramount importance of technological advancement in delivering the highest quality products and services to our clients. To ensure exceptional quality, our washline for flakes is equipped with TOMRA optical sorters, guaranteeing the utmost precision and purity of our flakes. Moreover, our investment in a STARLINGER extrusion machine, scheduled to commence operations in January 2024, will significantly enhance our production capacity of top-tier plastic products, further meeting the evolving needs of our clients.

Quality is our priority, and we take meticulous measures to ensure the careful treatment of flakes throughout the recycling process. Our advanced recycling lines are specifically designed to minimize dust, high IV loss, and degradation. By incorporating a high-vacuum degassing extruder, we effectively reduce viscosity loss during extrusion and purify the melt, eliminating any volatile contamination. This approach guarantees the production of high-quality rPET, meeting the stringent standards of our clients.

Traceability is a fundamental aspect of our operations, and we have implemented a state-of-the-art traceability system that monitors the entire lifecycle of our plastic, from sourcing to production. This system enables us to ensure transparency, accountability, and environmental stewardship. By leveraging the latest technologies on our production line, we enhance our environmental performance, mitigate risks to human health, and solidify our reputation as a responsible and sustainable business.

To optimize our operations, we have implemented inline crystallization a er underwater pelletizing, which not only minimizes our facility’s footprint but also results in energy savings and achieves high crystallinity in the final product. Additionally, our inline color measurement technology guarantees first-class color value, ensuring consistent and exceptional visual appeal in the produced rPET

To optimize our operations, we have implemented inline crystallization a er underwater pelletizing, which not only minimizes our facility’s footprint but also results in energy savings and achieves high crystallinity in the final product. Additionally, our inline color measurement technology guarantees first-class color value, ensuring consistent and exceptional visual appeal in the produced rPET

As Mohinani Group, we stand at the forefront of PET recycling in Ghana and beyond. Our pioneering RPET project underscores our unwavering commitment to waste management and sustainability. By investing in cutting-edge technologies, implementing traceability systems, and providing top-quality plastic flakes, we ensure a brighter and cleaner future for generations to come. Together, let us transform the landscape of plastic packaging, promote a circular economy, and lead the way towards a sustainable future.

Transforming Pet Waste Into New Bottles

Mohinani Group proudly presents our RPET Project — an innovative initiative aimed at

revolutionizing waste management by harnessing the potential of PET (Polyethylene

terephthalate) waste. Our goal is to produce food-grade bottle to bottle pellets and high-grade

flakes, which will be utilized in the manufacturing of new bottles. This project represents our firm

commitment to closing the loop for plastic packaging and prioritizing sustainable practices in

Africa.

As part of our dedication to innovation and sustainability, we have invested in cutting-edge

Starlinger recoSTAR PET 165 HC iV+ bottle-to-bottle recycling lines. These state-of-the-art

recycling lines have been strategically installed in our new plants located in Ghana and Nigeria.

We are proud to announce that our Ghana facility is the first-ever bottle-to-bottle recycling plant in the country. This significant milestone emphasizes the critical importance of waste management in Africa and showcases Mohinani Group’s unwavering commitment to promoting a circular economy for plastic packaging. We firmly believe that by setting a pioneering example, we can inspire others in the industry to adopt sustainable practices.

Traceability is a fundamental aspect of our operations, and we have implemented a state-of-the-art traceability system that monitors the entire lifecycle of our plastic, from sourcing to production. This system enables us to ensure transparency, accountability, and environmental stewardship. By leveraging the latest technologies on our production line, we enhance our environmental performance, mitigate risks to human health, and solidify our reputation as a responsible and sustainable business.

To optimize our operations, we have implemented inline crystallization after underwater pelletizing, which not only minimizes our facility’s footprint but also results in energy savings and achieves high crystallinity in the final product. Additionally, our inline color measurement technology guarantees first-class color value, ensuring consistent and exceptional visual appeal in the produced r-PET